Fabric & Printing Processes

Let’s talk more about fabric and printing processes. Long story short – the fabric used determines the printing process utilised which influences the colour options.

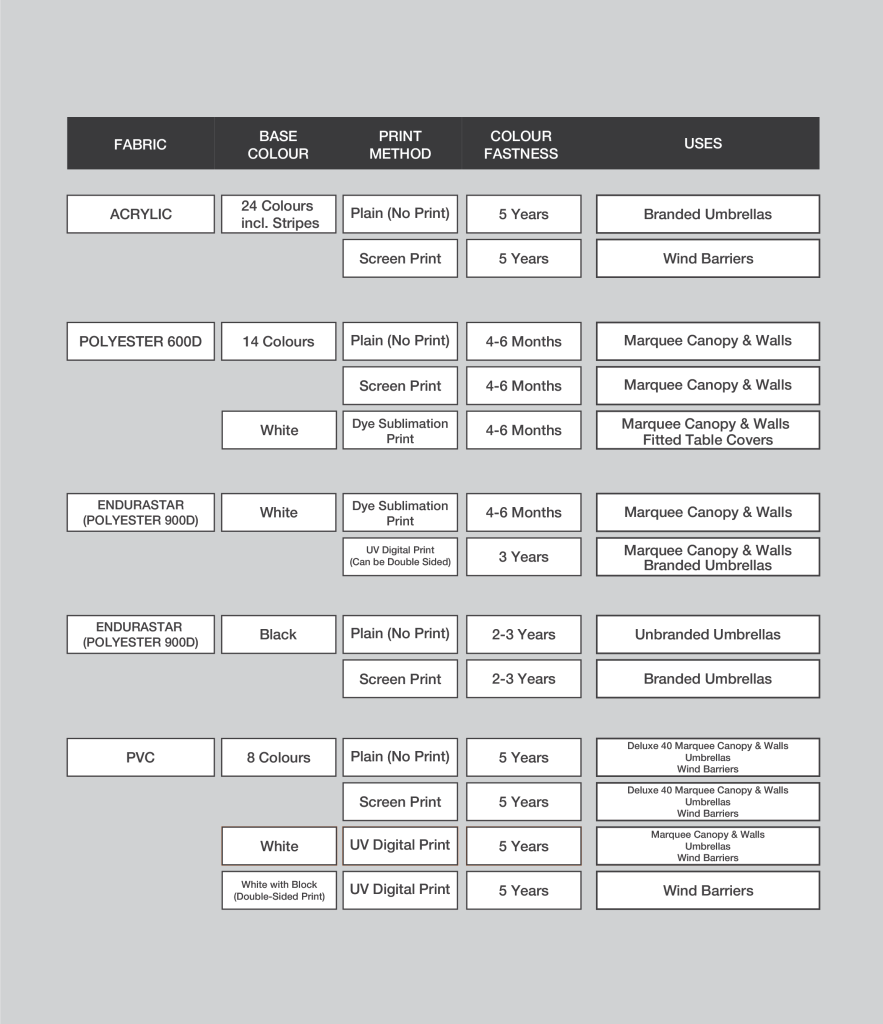

The below table indicates each fabric we use and the printing process used for that fabric. Don’t get overwhelmed! We have some good information on what it all means below. Any questions? We’re always here to help on 1300 721 877.

Fabrics

Acrylic Canvas

Our acrylic canvas fabric is a synthetic woven material equipped to withstand the harsh outdoor elements long-term.

Acrylic fabric is built to last with advanced durability and is manufactured in a range of stock colours with an exceptional colour fastness of 5 years. Star Outdoor acrylic fabric is made in Spain and available in up to 24 different base colours including stripes, to ensure you have a diverse range of colour options to suit your needs. The acrylic fabric uses either plain (no print) or screenprint printing method.

Our acrylic canvas fabric is easy to maintain and clean. Everyday dirt and debris can be removed with a vacuum or gentle brushing. Warm water (maximum temperature of 30°C) and soap combination can be used occasionally for a more thorough clean. However please ensure the fabric dries completely before storing.

When screenprinting on Acrylic the dye is added to the liquid fibre solution before the fibre is extruded. This means the ink colour is spread completely through the fibre giving it superior colourfastness and weathering.

For more information about our acrylic fabric please visit https://recasensusa.com/

Polyester 600D

The D is a unit of measurement, ‘denier’ which is referencing the thickness of the material. The higher the denier measurement, the thicker the fabric and more abrasion-resistant.

Our polyester 600D is the most cost-conscious option for events or intermittent use.

Polyester 600D is a reliable fabric with a good degree of thickness. It is available in 14 different base colours options with either plain (no print) or screenprint printing method. Polyester 600D is also available in a white base colour with dye-sublimation printing. These options have a colourfastness of 4-6 months.

When screenprinting on Polyester 600D the dye is applied after the yarn is produced and therefore does not penetrate the core of the fibre.

EuduraStar Polyester 600D

EnduraStar Polyester 600D is also available in a black base colour with either plain (no print) or screenprint printing method. EnduraStar Polyester 600D has an estimated 2-3 year colourfastness with the black base colour, making it a cost-effective option for longevity.

EuduraStar Polyester 900D

EnduraStar Polyester 900D is a heavy-duty fabric with a higher degree of thickness and abrasion resistance compared to the 600D. EnduraStar Polyester 600D is available in a white base colour with dye-sublimation and UV Digital printing. These options have a 4-6 month or 3-year colourfastness, respectively. UV digital printing is available in double-sided printing and is very popular with branded umbrellas.

When screenprinting on EnduraStar 600D and EnduraStar 900D the dye is added to the liquid fibre solution before the fibre is extruded. This means the ink colour is spread completely through the fibre giving it superior colourfastness and weathering.

How to maintain your Polyester 600D and EnduraStar Polyester 900D fabric

Your Polyester 600D and EnduraStar Polyester 900D fabric can be cleaned using a mild soap and warm water (maximum temperature of 30°C) solution. Allow to air dry completely before storing. Before cleaning all over we recommend patch cleaning on a small area first to ensure the solution does not affect colourfastness.

PVC Fabric (Vinyl)

The durable and flexible quality of PVC fabric makes it the best option for some speciality items. PVC material is highly durable and has superior resistance to tearing and environmental elements. PVC fabric is available in 8 stock colours with plain (no print) or screenprint printing methods with a 5-year colourfastness. It is also available in a base white colour or white with a block out film in the middle, which allows for double-sided printing with UV digital printing, and no show through from the other side. The UV Digital print allows for a colourfastness of 3 years.

To ensure your PVC fabric is maintained we recommend using a mild detergent and warm water (maximum temperature of 30°C) solution and using a non-abrasive cloth to clean the material. Allow to air dry completely before storing. Before cleaning all over we recommend patch cleaning on a small area first to ensure the solution does not affect colourfastness.

Printing Methods

Screenprinting

Screenprinting is available with our Acrylic, Polyester 600D, EnduraStar 600D, Endurastar 900D and PVC fabrics.

Screenprinting involves pressing ink through a stencilled artwork screen to create the print on the fabric surface. Screenprinting allows for a few vivid colours to be used across a range of colour bases, including darker tones. A new stencil is used for each colour used in the artwork and applied as individual layers to the fabric surface.

Dye-Sublimation

Dye-sublimation printing is available with our Polyester 600D and EnduraStar polyester 900D.

Dye-sublimation printing allows for excellent colouring and an emphasis on finer details. It is ideal for printing colourful and photographic artworks. Dye-sublimation print is a heat-transfer print wherein ink is transferred into white yarn fibres with heat and pressure. The outcome is a smooth and realistic artwork with vibrant colours and sharp lines.

The colourfastness of dye-sublimation print is 4-6 months, making it the optimal choice for events or intermittent use.

UV Digital

UV digital print is used for our EnduraStar Polyester 900D and PVC with a white or with block base. The PVC white base with block allows for double-sided printing.

UV Digital printing uses ultraviolet light (UV light) to dry or cure the ink almost instantaneously when it comes into contact with the fabric. As the ink is printed onto the fabric the UV light dries it immediately, which allows for finer lines and details as the ink does not have time to soak into the fabric before drying. UV digital printing allows for sharper colours, a gloss finish, better weather resistance and durability, making it ideal for outdoor use.